Aseptic Filling Machines - pharmaceutical Packaging

Aseptic filling solutions for pharmaceutical and biotech products. Choose the Optimal Solution for Your Application from Our Extensive Portfolio 90 Years of Experience · Worldwide Services · Cutting-edge Technology · Customized Solutions

A Ultimate Guide to Aseptic Filling Technology for PET ...

Learn everything about aseptic filling technology for bottled beverages - the sterilization processes, equipment, and more.

Aseptic Filling & Dry Ultra-clean Filling - PHS | Tailor ...

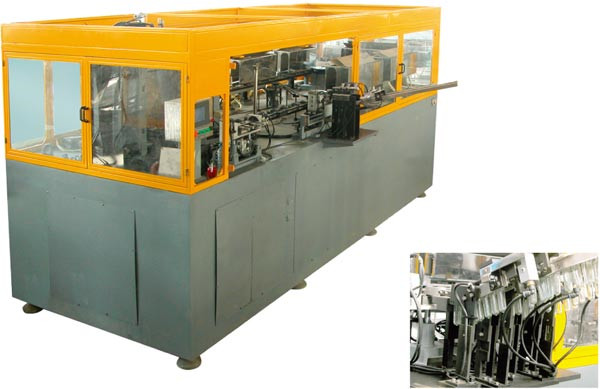

Dry Ultra-clean Filling. Aseptic filling technology can be applied to non-carbonated products, beverage products without preservatives for long-term maintenance, high acid/low acid/neutral beverages, and PET bottle beverage products. Capacity; 5000-48000BPH/ (500ml) Container Formats; 50-120mm/Dia. 120-320mm/Height. Sterilization Capability; 6D.

Newamstar Ultra-Clean Aseptic Cold Filling System

Newamstar owns the domestic exclusive mature medium and high speed PET bottle ultra-clean filling technology, which has a wide adaptability for beverage products. Aiming at high acid or low acid product, the whole system could achieve the sterilization efficiency 5D or 6D.

Hot Filling Vs Aseptic Cold Filling: 6 Key Differences

Hot filling and aseptic cold filling have pros and cons for beverage production. Compare in terms of quality, bottles, environment, costs and more.

Complete Aseptic PET lines - SIDEL

Aseptic Lines. Perfectly defined liquid recipes and processing methods, combined with the right PET bottle and aseptic packaging solution, can ensure maximum product integrity along the supply chain for juices, nectars, soft drinks, isotonic and teas (JNSDIT) as well as liquid dairy products (LDP), while optimizing uptime, costs and sustainability.

A cleaner type of filling - Cleanroom technology

Cold-aseptics beat hot filling For filling PET bottles with sensitive beverages, there are two safe technologies from a microbiological viewpoint: hot filling and cold-aseptics. Both of them, naturally, have their advantages and disadvantages.

About | Aseptic Line | Aseptic Filling Line

Tailor made, provide you complete turnkey solution. Newamstar medium-and-high-speed PET bottle aseptic cold filling technology can be applied to a wide range of beverage products.

The advantages of cold aseptic filling - Processing Magazine

Flexibility: Most aseptic filling lines can be configured to supply a range of products and fill a range of containers including PET, HDPE, LDPE, glass, cans, foil and more.

Aseptic Processing& Cold Aseptic Filling - PHS

Aseptic filling technology aims to achieve the best filling speed, accuracy, and flexibility while maintaining the sterility of the product and containers throughout the process.

Ultra-clean Filling | Aseptic Filling Line

The 36,000BPH ultra-clean carbonated production line delivered this time is Tsingtao’s first PET bottle blowing-filling-capping…