Aseptic Filling & Dry Ultra-clean Filling - PHS | Tailor ...

Dry Ultra-clean Filling. Aseptic filling technology can be applied to non-carbonated products, beverage products without preservatives for long-term maintenance, high acid/low acid/neutral beverages, and PET bottle beverage products. Capacity; 5000-48000BPH/ (500ml) Container Formats; 50-120mm/Dia. 120-320mm/Height. Sterilization Capability; 6D.

Hot Filling Vs Aseptic Cold Filling: 6 Key Differences

Hot filling and aseptic cold filling have pros and cons for beverage production. Compare in terms of quality, bottles, environment, costs and more.

The advantages of cold aseptic filling - Processing Magazine

Quality: Probably the biggest driver toward aseptic filling is the improvement in product quality. Any heat treatments can be driven by product requirements, rather than the need to sterilize the container, making high temperature, short time (HTST) pasteurization feasible in many cases.

Beverage Packaging: Exploring Filling Technologies

With the hot fill technology it is possible to fill at 90°C, guaranteeing a constant filling temperature, filling level accuracy and total product recycling.

The Ultimate Guide To Aseptic Filling Technology

1. The main advantages of sterile packaging. 1.1 Under sterile conditions, aseptic packaging can retain food’s nutritional content and flavor to a greater extent while reducing loss. Aseptic packaging facilitates ultra-high temperature instant sterilization methods to disinfect food before packaging, whereas other forms are complex.

ProFill V Series Rotary Can Filler | Beverage Can Filling ...

The ProFill V series of Volumetric can fillers are accelerating plant production everywhere. These can fillers run at speeds between 100 – 600+ cans per minute while achieving precise and consistent filling volumes in multiple can sizes for a variety of beverages and liquids.

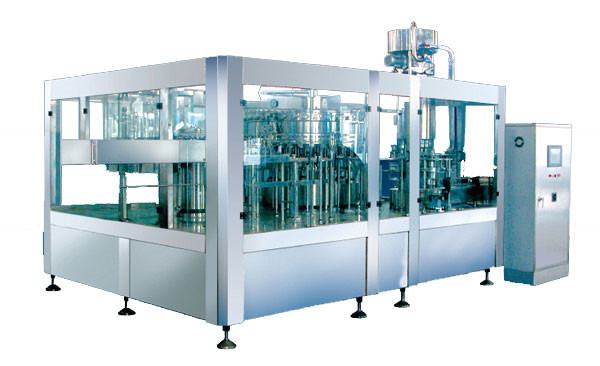

Ultra-clean filling | High End Filling And Packaging ...

Specially designed stainless steel gripper for rinser which is solid and durable, no contacting bottleneck to avoid second contamination to bottleneck. High-speed and mass flowrate filling valve is easy to clean, with perfect CIP loop and control program. The bottle-out starwheel is a helical structure.

Ultra-Clean Fill Hood - Simulate Commercial Aseptic Filling

MicroThermics’ Ultra-Clean Fill Hood is a user friendly, flexible way to fill samples into pre-sterilized containers in an ultra-clean environment to simulate commercial aseptic filling. This is an excellent way to create ESL and sterile samples for tradeshows, taste panels, stability and shelf-life studies and more!

Hot, cold or aseptic filling: what is the best choice?

Hot filling is designed for still products, without CO2, for any PH and density, such as juices, nectars, jams, preserves, tea, non-sparkling beverages with and without preservatives.

Cold-aseptic fillingCold-aseptic filling :: FoodProcessing

Aseptic filling is recommended for beverages such as fruit juices, tea beverages, sports drinks, vegetable juices, milk-based mixed drinks, UHT milk, near-water drinks and flavoured waters. It can be used for both still and carbonated beverages.