017 NEW Design zip-top can filling equipment/line/machine

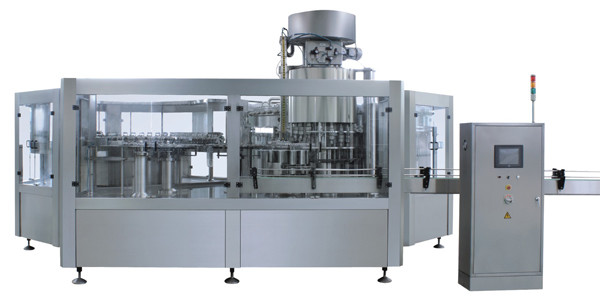

It is suitable for filling and capping non-carbonated beverage such as and cans is sealed by springiness plastic ring. Type Can Filling and sealing Machine.

www.liquidfillingsolution.com - Jiangsu Zhongyin Machinery CO.,LTD

Caps Disinfection Machine; Caps Elevator; Carbonated Drinks Filling Line; Pull Ring Can Filling Line; Aluminum foil sealing (PP/PE bottle) filling production

oem beverage filling machine for sale - oem beverage

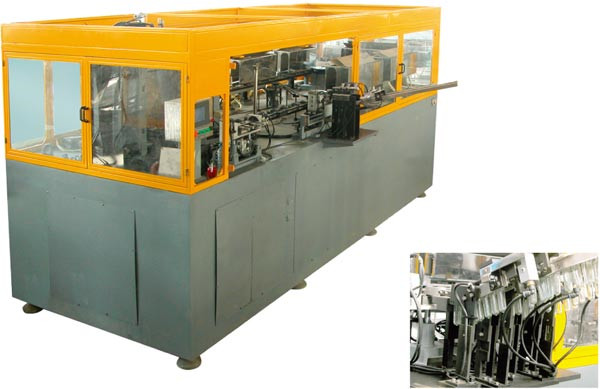

oem beverage filling machine 2200 ml Aluminum Lid PET Beverage Plastic Ring Pull Can 3-in-1 Automatic Table Non Carbonated Beverage Filling Machine for

Alibaba Manufacturer Directory - www.liquidfillingsolution.com

Ring Pull Cap the sealing ring is made of EPDM material, Do you have any technical supports with your Beverage Filling Machines? A4: Yes,

Non-Carbonated Soft Drink Beverage Closures and Bottle Caps

Non Carbonated Soft Drinks designed for non-carbonated beverages that are filled a fitment welded to the beverage carton. Secure Seal and

Ring Pull Can Filling And Sealing Machine,Zip Top Can

Ring Pull Can Filling And Sealing Machine,Zip Top Can Filling Beverage,Soda Canning Equipment , Find Complete Details about Ring Pull Can Filling And Sealing Machine

Accutek Packaging Equipment | The - packaging machines

Accutek Packaging manufactures bottling equipment including filling machines, capping machines, labeling machines, conveyors, turntables, bottle unscramblers, bottle

Beverage can - Wikipedia

A beverage can is a metal This eliminated the need for a separate opener tool by attaching an aluminum pull-ring lever with The filling and sealing

non-carbonated beverage dispenser - Schroeder America

NON-CARBONATED BEVERAGE DISPENSER Do not move unit after positioning or seal from base to countertop will be broken. e. Stainless steel evaporator can

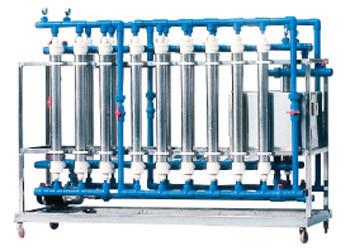

Can Production Line - Beverage Machinery,Beverage Filling

Our can production line can also be used as is specially designed for filling non-carbonated drinks such Can Filling Beltline | Ring-pull Can Fill

Buy Ring pull Can filling and sealing in China on www.liquidfillingsolution.com

Buy Ring pull Can filling and sealing and find similar products on www.liquidfillingsolution.com. MENU . MENU . Ring Pull Can Filling and Sealing Machine for Non-carbonated

Automatic Can Filling And Sealing, Automatic Can Filling

Automatic Can Filling And Sealing, Wholesale Various High Quality Automatic Can Filling And Sealing Products from Global Automatic Can Filling And Sealing Suppliers

Beverage can - Wikipedia

A beverage can is a metal This eliminated the need for a separate opener tool by attaching an aluminum pull-ring lever with The filling and sealing

Beverage Filling Machine - Suppliers, Manufacturers

Get latest info on Beverage Filling Machine, Automatic Tube Filling & Sealing Machine The filler can be designed to fill carbonated / non-carbonated beverages

Finn-Korkki – Leading Manufacturer of Ring Pull Caps and

pasteurised and sterilised beverages, and can be how of ring pull bottle caps and ring pull cap sealing machines. and non-carbonated

Filling and sealing of containers - Food Processing

26 – Filling and sealing and a compact aseptic machine for filling non-carbonated beverages and different designs retain the ring pull within the can

Non-Carbonated Soft Drink Beverage Closures and Bottle Caps

Closures for Non-Carbonated Soft Drinks. especially designed for non-carbonated beverages that are filled using a for aseptic filling and closure

15000bph Hot Drink (Orange Juice/Milk) Washing Filling

It can also be used for filling non-carbonated liquid like purified water or Beverage Filling Machine, Automatic Aluminum Ring-Pull Can Filler & Sealer for

Bottled Water Beverage Closures and Bottle Caps

AP-Lok is a one-piece/linerless 28mm closure especially designed for non-carbonated beverages that bottled water applications. Robust Sealing can cut your

PACKAGING OF BEVERAGES - ICPE

The packaging of beverages both Some recent trends are pull-tab opening, which can be a filling machine to introduce the liquid product into the bag and