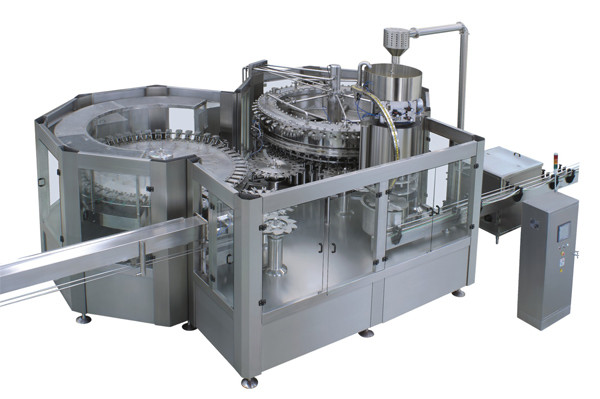

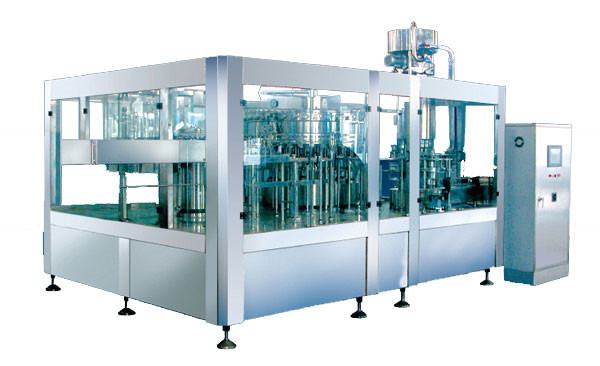

Filling Machine for Sauces - Liquid & Viscous Food Fillers

Filling Machines for Liquid & Viscous Sauces and Dressings in North America. Bottling Equipment for Sensitive Sauces and Dressings using Rotary Net-Weight Technology

sauce filling machine - Shop sauce filling machine

Get Deals and Low Prices On sauce filling machine At liquidfillingsolution. Discover the Future Of Cooking With the High-Tech Gadgets For Food Lovers.

Tetra Pak® CIP unit P cleaning-in-place system

Tetra Pak ® CIP unit P is an advanced automatic cleaning-in-place system used for cleaning process equipment such as filling machines, pasteurisers, sanitary pipes, tanks, aseptic tanks, plate heat exchangers etc.

Liquid Filling Machines for Sauces & Dressings in Bottles or ...

Discover our hygienic liquid filling and capping machines designed specifically for sauces and dressings in bottles or jars. (Up to 36,000 bph)

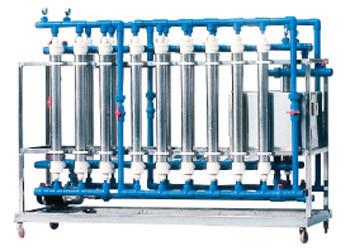

5 Steps in a Common Food, Dairy, and Beverage Clean-in-place ...

CSI has the ability to engineer, design, and fabricate a custom clean-in-place system to meet your exact hygienic processing needs. CIP equipment from CSI helps you diagram, control, monitor, and document the cleaning methods that are essential to sanitary processing.

CIP Systems | Cleaning in Place Systems - IC Filling Systems

CIP Cleaning in Place Tanks. IC Filling Systems offer a complete range of CIP systems (Cleaning-In-Place) suitable from the smallest micro-brewery to the largest bottling plant. Our CIP machines are particularly versatile and offer a range of solutions for every budget from a smallest CIP of 2 tanks of 150 litres to the largest of 3 tanks of ...

white paper template.indd - JBT

The development of clean-in-place (CIP) technology, i.e., the automatic, reproducible and reliable delivery of cleaning solutions, rinse and wash water to and through process equipment and process piping, has improved both product quality and plant hygiene.

Filling Machines and Clean in Place Systems

Not only do the CIP systems clean and sanitize the product pathway of the liquid fillers, but they also allow the operators of a packaging system to attend to other tasks while the cleaning of the filling machine takes place.

Considerations for effective cleaning-in-place (CIP) systems

CIP systems should ensure that no cleaning fluids or contaminants remain in the equipment – ensuring food safety, and by reducing the effort and downtime required for cleaning, they also ensure production cycles are efficient and cost-effective.

Mastering CIP: Best Practices for Effective Cleaning in Place ...

Discover essential guidelines for designing and operating Cleaning in Place (CIP) systems. Learn about the fundamental principles of CIP, including time, temperature, titration, and turbulence. Enhance your understanding of CIP to ensure optimal cleanliness and productivity.

CIP in the food industry | Cleaning-in-place system | Endress ...

One major trend in the food industry is the use of inline process measurements to control cleaning temperature, flow, and detergent concentration. To optimize CIP systems and therefore save raw materials and energy, fast phase shifts in the return line are detected with optical systems.

What is Clean in Place (CIP) and Best Practices - Parsable

Clean-in-place (CIP) systems quickly and thoroughly clean processing equipment without requiring the removal of components. Businesses that incorporate CIP solutions enjoy numerous benefits, including reduced downtime, increased production, and enhanced product safety.