Automatic Bottling Machines - Inline Bottling Systems - kinexcappers.com

Our industry experts are ready to help you upgrade your bottling line to full automation. Choose from a variety of capping machines, filling machines, and conveyors ES Electric Bottle Cappers ES Bottle capping machines provide outstanding torque accuracy and ... PS Pneumatic Bottle Capper PS Bottle Cappers are an outstanding combination of ... ES Table Top Capping Equipment Tabletop bottle capping equipment that provides outstanding ... Cap-Rite Manual Cap Tightener Hand-Held Bottle Cap Tightener For Low Production Runs LS Pneumatic Cap Tightener Tightens screw and lug caps from 24mm to 83mm in diameter. Kinetic Bottle Capper Rugged, reliable Bottle Cappers and decapper machines that are ...

Water Bottling Machines, Water Bottling Equipment, Bottling ...

Cached28/06/2020 · These water bottling machines can produce from 150 bottles per hour all the way up to 3,000 bottles per hour and can accommodate a variety of bottle sizes. If you are looking to upgrade your existing lines or add a new line, Velocity Equipment Solutions has the right water bottling machines for your needs.

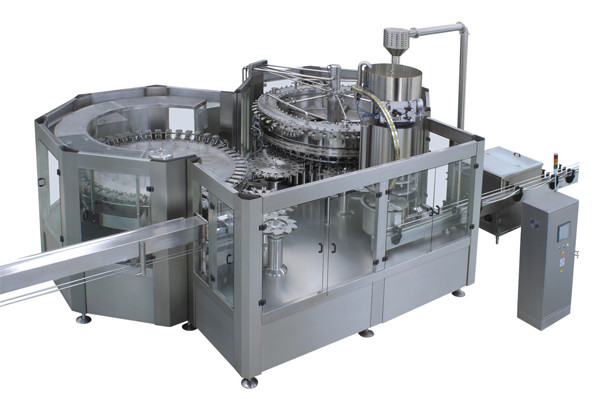

Medium Size Drink Pure Water Bottled Filling Equipment

CachedBottled Water Filling Machines and Equipment Guide . Bottled Water and Beverages Filling Machinery Guide: Inline Filling Systems offers a wide range of complete bottled water filling equipment with production ranges from entry level producing 600 containers per hour to systems pushing 9000 containers per hour depending on the bottle characteristics.

Water bottling plant - Comac - Comac Group

CachedWater Bottling PlantsWater Bottling Systems, Filling Lines and PlantsWater Bottling ProcessWater Bottling Machine Manufacturers: Why Choose ComacThe main advantage of choosing Comac is our capability to offer a tailor-made glass water bottling plant according to specific technical requirements. You can create complete bottled water production linesstarting from the beginning and designing it to fit within the space available. During each step of the production, we make sure that the original characteristics of the water are not altered throughout the bottling process. Our water bottling plants can also be easily adapted to the existing systems and integrated in the operating stream to rinse, fill and cap bottles of water. Let’s get more in details about water bottling machinery. We supply three main kinds of automatic water bottle filling systems, all suitable for glass bottle filling: 1. Automatic systems up to 8000 BPH 2. Automatic systems up to 12000 BPH 3. Automatic systems over 12000 BPH See full list on comacgroup.com As we have written above, our water bottling systems can also be integrated within the existing plants. In addition, you can accessorize them with a series of machines that carry out the whole water filling process. 1. Saturation unit– Made of AISI 304 stainless stell, its aim is to deaerate water and carbonate it through the direct injection of CO2. The CO2 amount is set by modulating valve, which provides several degrees of carbonation. 1. Premix unit– Deaeration and carbonation of water are also carried out by the premix unit, which is made of various components such as the deaeration tank, the syrup tank, the mixing water/syrup unit, the carbonation device and the stabilization/storage tank. There exist three types so to meet the specifications of small, medium and big-sized businesses: Premix 20000l/h, Premix 10000 l/h, Premix 5000 l/h. 1. Tunnel of heating and cooling– Made of stainless stell AISI 304, it brings the previously packaged drinks to room temperature. Allthe tanks... See full list on comacgroup.com The process carried out by a water bottling plant includes three or four steps, depending on your decision to produce carbonated water or not: 1. Cleaning– Cleaning of the empty bottles is probably the most important step in a water bottling plant. The reason is simple, a proper cleaning is the only way to grant hygiene and safety to the water you are bottling. It would be a great mistake to sterilize water before the bottling, and then contaminate it just in the final process of the production! Therefore, choose only the best providers as far as cleaning machines are concerned. Quality machines are made only with the best materials, resistant to rust and corrosion, and can be sanitized whenever you need. 1. Filling– Filling the bottles with water is obviously the aim of any water bottling plant. This process is quite simple: the bottles are grabbed by some grippers, while the above nozzles pour the water into them. If you choose to bottle your water into glass only, you would bette... See full list on comacgroup.com Since 1990 we have been manufacturing water bottling machines for activities of any size all over the world, even in far-away countries like the US. In fact, our plants have some features that turn them into a good investment that helps you solve productivity problems for what concerns water filling – all Comac water bottling plants are: 1. Manufactured with stainless steel AISI 304, a special alloy that features a high resistance to acid materials, rust and corrosion, granting the best level of hygiene and endurance 2. Compact, versatile and easy to install in small spaces 3. Customizable according to your needs Looking for suppliers of water bottling equipment? See full list on comacgroup.com

Automatic Table Water Bottling Equipment with Medium Capacity

CachedAutomatic Table Water Bottling Equipment with Medium Capacity Bottled Water Filling Machines and Equipment Guide | Inline Filling Inline Filling Systems builds bottled water systems and filling machines, bottled water packaging machinery and bottled water Bi-Directional Tables Combination Bottle Cleaner production speed limited by other components.

Bottling plants - Comac Group

CachedBottling plant for medium and big industries. For higher volumes of production, Comac created different bottling plants for medium and big industries: two systems capable of processing more than 6,000 glass bottles per hour. These bottling plants provide the same features of the other models, on a higher scale: they can carry out the rinsing, filling and capping of bottles.

Water Bottle Filling Equipment for Sale - Liquid Packaging ...

CachedE-PAK Machinery offers a wide range of machinery solutions capable of filling for low-viscosity liquids such as water. We recommend the following solutions: Gravity, Pressure, & Vacuum Overflow Bottle Fillers . These types of fillers are all helpful when filling thin to medium viscosity liquids, hence a perfect fit for water bottles.

Automatic Bottling Machines - Inline Bottling Systems - kinexcappers.com

Our industry experts are ready to help you upgrade your bottling line to full automation. Choose from a variety of capping machines, filling machines, and conveyors ES Electric Bottle Cappers PS Pneumatic Bottle Capper ES Table Top Capping Equipment Cap-Rite Manual Cap Tightener LS Pneumatic Cap Tightener Kinetic Bottle Capper