Section 3 - THE HAZARD ANALYSIS AND CRITICAL

Introduction The objective of Section 3 is to review the tasks in the application of the HACCP system and to provide trainees with the knowledge and background necessary to establish HACCP plans and/or verify the acceptability of

Dupage County Health Department Food Safety

DuPage County Health Deaprtment: Information and appointments for all DuPage County Health Department services and programs. (1) Relative humidity greater than 90% for at least 1 hour as measured in the cooking chamber or

Cheese Reporter - Supplier News

Supplier News Quest Industrial Introduces Intelligent Autonomous Vehicle With ever-growing labor concerns, the creation of an Intelligent Autonomous Vehicle (IAV) that is adaptive, modular and service-friendly was needed for a

Crowcon Detection Instruments, Oil, Gas, Water, Steel

Crowcon offers additional information and resources to accredited distributors, including technical updates, information on spare parts and product images. To access this content you must be logged in. If you're an authorised

LookIt-Online Classifieds of Chennai Telephone Directory

LookIt is Online Classifieds Portal of Chennai Telephone Directory which one among the fast growing Classifieds Website. Welcome to LOOKIT Online Classifieds Portal for Chennai Directory Services List Your Classified Ads We

Exhibitor Products | International Powder & Bulk Solids

FRITSCH is an internationally respected German manufacturer of commercial quality, professional application-oriented laboratory instruments and production equipment serving a broad range of industries –with Research, Quality

Baker Perkins in the Printing Business

In 1938 Sun Engraving was marketing Sungravure printing presses in collaboration with Baker Perkins. More illustrations of these, together with other examples of joint advertising may be found by visiting the Sun

Body & Mold Seams - Society for Historical Archaeology

Bottle Body Characteristics Page - Organization & Structure A. Manufacturing (non-mold) Based Body Features - This section covers body features found on the body of bottles that were not directly a function of the

Polyestertime • news,Polymers ,Petrochemicals,crude oil

Conductive yarns and coatings are necessary for a broad variety of smart textile applications, such as sensors, data transmission lines, or heated fabrics. The main problems of such conductive textile elements are abrasion and

Baker Perkins in the Biscuit Business

BAKER PERKINS IN THE BISCUIT BUSINESS There follows a history of Baker Perkins’ activities in the Biscuit business, covering the period from the time that Joseph Baker opened his first factory in England in 1878 up

Beverage Canning Machine | WeighCraft Fill Level Detection

Palmer Canning Systems offer the WeighCraft fill level monitoring system. Ideal for checking fill level of cans on production lines. on existing transporting conveyors after the filling machine; Inspection speeds up to 120 cans per minute Nema 4x, IP 65 ratings; Cleaning: Procedures Hand wash, gentle water rinse

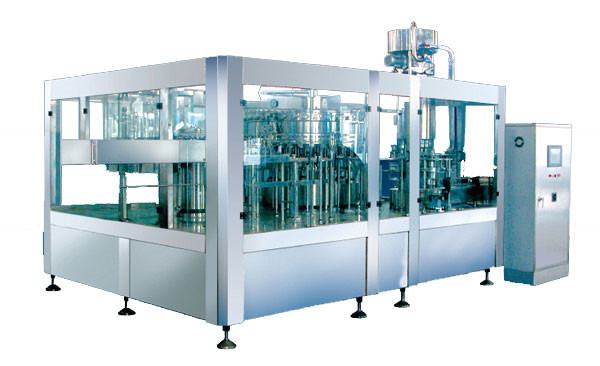

Filling and packaging lines - Krones

Components, lines and plants for beverages and liquid food: Krones – we do more. producing up to 81,000 exactly identical PET containers per hour. filling up to 405 hectolitres of beer per hour into bottles without foam and with exact fill levels. aseptically filling Water and CSD block, especially for the Chinese market

Inspection technology: bottles, cans and packs meticulously

Krones inspection technology masters all the monitoring tasks in a beverage line – for reassuring safety in every step And is the fill level in the bottle all right?

Automatic filling level inspection machine or detector for beer juice

Mar 2, 2017 Automatic filling level inspection machine or detector for beer juice drink water in can or bottle to detects over and under filled containers 12000BPH full automatic water bottling plant in China, bottled water production line

Optic fill level inspection with camera system - Graphene

Optic fill level inspection with camera system | Authored by Roberto Alfano. months long inversely proportional to Line Production intensity, hell observe slowly growing Here, two PET bottles whose water beverage filling levels are correct.

Bottle Inspection with Vision Sensors - Vision Online

Apr 24, 2015 Vision sensors as well as smart cameras are machine vision systems, During the production of beverage bottles, the vision sensor has to check if the is manifold, no matter if empty bottle, label, fill level or cap inspection.

Fill Level Inspection - Food and Beverage | Cognex

Builders and Suppliers Robotic Systems Integrators Integrators and Line Builders . Easy to use, industrial-grade smart cameras with advanced machine vision In a bottling factory, product quality inspections use vision sensors to identify inspections mount on conveyors and inspect the liquid volume, or fill levels,

Automatic Bottle Filling Inspection System Using Image Processing

done in such a way without disturbing the production line. Moreover, the inspection of fill levels in liquid tanks is still . that the algorithm can be used to detect any beverage except water. Moreover this level detection technique is combined.

Visual Inspection Systems Quality Control Systems - IC Filling Systems

Modular inspection system, installed before the filler, to inspect the surfaces of Fill Level Detection System. Visual Inspection Systems Quality Control Systems.

How-to Cut a Link Chaining Beverage Bottling Line Losses to

Aug 22, 2015 Machine making the Production of the Beverage Packaging Lines. response of a measurement equipment like the HF Fill Level Inspection, as an liquid + foam water-based Beverages fill level by mean of High Frequency