Lifecycle of a Plastic Product - American Chemistry

Since 1977, the 2-liter plastic soft drink bottle has gone from weighing 68 grams to just 47 grams today, representing a 31 percent reduction per bottle. That saved more than 180 million pounds of packaging in 2006 for just 2-liter soft drink bottles. The 1-gallon plastic milk jug has undergone a similar reduction, weighing 30 percent less than what it did 20 years ago.

FAQs – SodaStream

Since plastic degrades over time and the bottle has to withstand recurring pressure from carbonation, it cannot be used forever. The expiration date on the bottle must be checked and new bottles purchased as soon as the former expires. The plastic bottles must also be replaced if put in the dishwasher, exposed to a heat source, or if they have become scratched. All components of carbonating

Labeling Equipment and Packaging Machinery | Busch Machinery

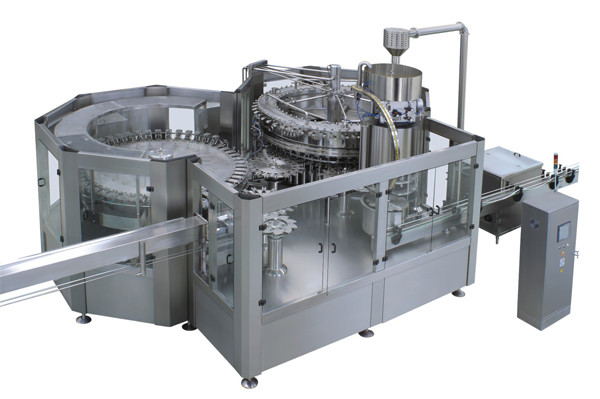

Counter pressure filling machines are specially designed for carbonated beverages, although they can also be used for non-carbonated products as well if there is need of a dual purpose machine such as soda and water bottling. The big difference between counter pressure filling machines and regular pressure fillers is the addition of a third filling tube to inject CO2 into the bottle while

Part III: Types of Bottle Closures

An early method of bottling carbonated drinks was called Hand and Knee Bottling, and involved an operator who sat at a hand operated bottle filling machine. Holding a bottle to the machine he raised a board under his knee, pressing the bottle's mouth to a tight fit and manually filling it, allowing excess pressure out before inserting a cork, which was then driven into the bottle with a

Beer bottle - Wikipedia

A beer bottle is a bottle designed as a container for liquidfillingsolution designs vary greatly in size and shape, but the glass commonly is brown or green to reduce spoilage from light, especially ultraviolet.. The most widely established alternatives to glass containers for beer in retail sales are beverage cans and aluminum bottles; for larger volumes kegs are in common use.

Blow molding - Wikipedia

In the United States soft drink industry, the number of plastic containers went from zero in 1977 to ten billion pieces in 1999. Today, an even greater number of products are blown and it is expected to keep increasing. For amorphous metals, also known as bulk metallic glasses, blow molding has been recently demonstrated under pressures and temperatures comparable to plastic blow molding

General Liability Classification Codes (Numbers

General liability classification codes are numbers that insurance companies use to put businesses into categories of risk. These ISO CGL codes help commercial insurers to underwrite & match premiums with exposures - which are used to determine your rates.

General Liability Industry Codes Lookup

Vending Machine Operations--Confection, Food, Beverage or Ice: 49618 : Vending Machine Operations--Tobacco Products: 49619: Vending Machine Operations: 49763: Warehouse--Cold Individual Storage Lockers: 49800: Wharf and Waterfront Property--Ferry Docks or Terminals: 49801: Wharf and Waterfront Property--Occupied by the Insured for Both Freight and Passenger Purposes: 49802: Wharf and

Processing at the juice packer | Orange Book

This section discusses the processing steps that take place in a juice packing plant up to the filling machine. Packaging activities are covered in section 9, “Packaging and storage of orange juice”, and the distribution of products to retailers is outlined in section 10, “From juice packer to consumer”. Capacities of juice packing facilities vary greatly – from small plants

Soda & Mineral Water

Probably the most comprehensive source of information on the history of soda water production in the liquidfillingsolution. is found in John J. Riley's 1958 (also reprinted in 1972) book entitled A History of the American Soft Drink Industry - Bottle Carbonated Beverages 1807-1957. (Much of the history in the following two works comes from Riley.) Schulz, et al. (1980) work entitled