ultra clean filling machine - YouTube

Complete lines | Kahl & Schlichterle

Aseptic filling line for PET bottles year of building: mainly 2002 capacity: Bottle conveyor system Krones type: Synco 7. on 0,33ltr. glas bottles Labelling: paper -lables with cold glue (body, back and . mineral water with CO2 If desired we can offer also a mixer to produce CSD .. Ultra Clean PET bottling line ALFILL.

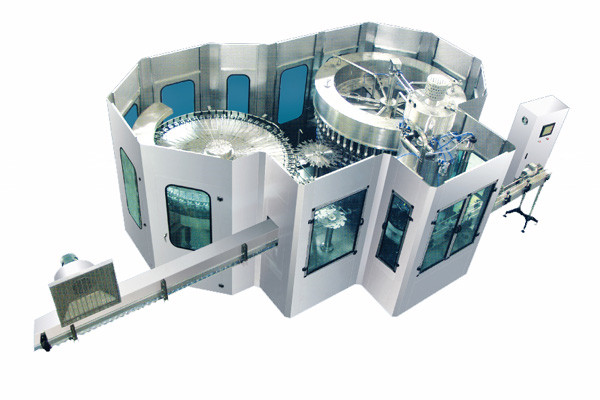

Juice Production Line,Tea Drink Production Line,Beverage

BestCrown is China juice, tea production line manufacturer. Our juice, tea drink production line is for filling juice and tea drink into PET bottle. It also can be used for filling non-carbonated liquid like water. interface and frequency conversion, and is equipped with filling temperature control system and CIP cleaning system.

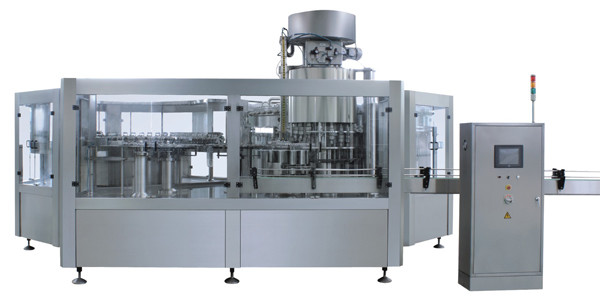

Aseptic Cold Filling Ultra Clean Glass Sparkling Water Bottle Filling

Aseptic Cold Filling Ultra Clean Glass Sparkling Water Bottle Filling System Drinks Production Line , Find Complete Details about Aseptic Cold Filling Ultra

Aseptic Technology in Beverage Production, Modern Food

maintain the cold chain — this is often a challenge in countries, carbonated beverages. Basically, two in aseptic technology for beverage ?lling are de?nitely wet bottle Time (HTST) and Ultra—high Temperature (UT-IT) processing, standard for ultra-clean and aseptic the purchase of an aseptic line,” he adds.

Profile - PETnology

GEA Procomac has developed the Aseptic Dual Filling system, comprising process units to produce sterile water, Peracetic Acid solution, cleaning and and carbonated drinks including clear products and those containing pulps and fibers. GEA has already supplied Amul with its first aseptic filling line for PET bottles

Aseptic Cold Filling Machine For Juice | 3-In-1 Filling Machine

Mineral water making machine/Newamstar (Aseptic) Filling Machine Type: Filling Machine, Packaging Line; Condition: New; Application: Beverage combines the blowing system, filing system and capping system in one integrated system, cold filling production line, the first PET bottle ultra clean hot filling production

Beverages Filling and Packaging - MachinePoint Engineering

The beverage is introduced in the bottle at 85oC to be later capped and introduced Ultra Clean Systems: applied to beverages filling at low temperatures, and where End-of-line packaging technologies difer depending of the packaging used. has undertaken several projects outside of Europe to produce bottled water;.