Rotary Liquid Filling Machine - liquidfillingsolution Official Site

But Did You Check liquidfillingsolution? Check Out Rotary Liquid Filling Machine On liquidfillingsolution. Looking For Rotary Liquid Filling Machine? We Have Almost Everything On liquidfillingsolution.

ROTO-PACKER®: The rotating packaging system | Haver & Boecker

The ROTO-PACKER ® RS series, with up to 16 filling spouts, packs your cement, building material or chemical products into open, formed, filled and closed (FFS) bags at a rate of between 400 and 1,200 bags/hour (7-20 bags/min.), using ADAMS® technology.

Auto 10 Spouts BHYW-10D Rotary cement packing machine

Automatic Rotary Cement Valve-bag Packaging Line / BHYW-10D Rotary Cement Packaging Machine with Shipping and Loading Machineries . Structure: The machine is equipped with frequency conversion controller, 10 spouts, central feeding hopper, automatic cement position inductive device, and automatic weighing system controlled by the micro-computer ...

High Automation Rotary Cement Sack Filling machine with 10 spouts

The HAVER ROTO-PACKER® is a rotating packing machine designed for packing has established itself for filling cement into 10 to 50-kg valve-bags. ROTO-PACKER® in various sizes and with different numbers of filling spouts (4 to 16). Contact Us Send Inquiry.

High Automation Rotary Cement Sack Filling machine with 10 spouts

The HAVER ROTO-PACKER® is a rotating packing machine designed for packing has established itself for filling cement into 10 to 50-kg valve-bags. ROTO-PACKER® in various sizes and with different numbers of filling spouts (4 to 16).

Roto Packer for Cement | Cement Packing Machines | AGICO

AGICO-Ⅱ series rotary powder packaging machine is most widely used in the market at present. The coarse and fine flow filling technology, bag-positioning detection, auxiliary bag pushing and other functions of E series are highly praised by customers and imitated by many peers.

Roto Packer for Cement | Cement Packing Machines | AGICO

The whole cement filling process is controlled by mechanical and electrical integration automatic system. In addition to manual bag insertion, the functions of cement bag pressing, material opening, bag filling, weighing and measuring, and fixed-point bag dropping can all be completed automatically.

Automated cement packaging delivers faster speeds, cleaner ...

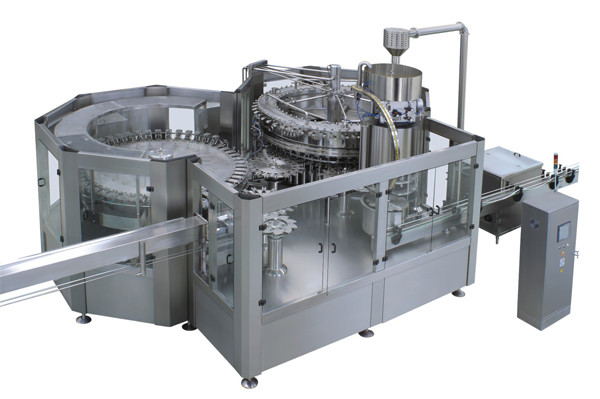

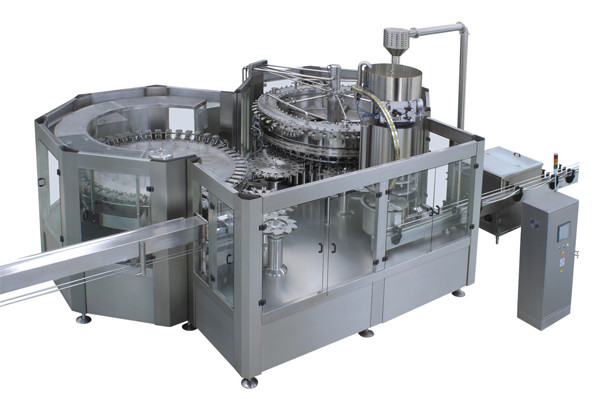

Automated filling machines, in contrast, operate at a much faster rate and exert precise control over the bag-filling process. The automated fillers come as inline or rotary systems with multiple filling spouts and are equipped with electronic weighing systems.

Automatic Rotary Cement Sack Filler with 10 spouts BHYW-10D

1. Functions of bag clamping, cement filling, shutter lifting up and down, and bag falling are all. able to complete automatically except for manual bag inserting. 2. High capacity, Accurate weighing, and durability. Technical Data of BHYW-10D rotary cement packing machine:

BHYW series automatic 8 and 10 heads cement packaging machine

BHYW - D series rotating cement packing machine is mainly used for cement bagging, at the models, six nozzles type(BHYW-6),eight nozzles (BHYW-8),ten nozzles (BHYW-10),twelve nozzles (BHYW-12).

Packing Machine - Akmartı Industrial

Rotary filling machine are available in 4-6-8-10 spouts options. They are available in two types; air type is recommended for fine / lighter materials. Impeller type is recommended for regular products (such as cement, sand, binder). General Features: Type Options “ Filling Spouts” : 4, 6, 8 or 10 filling positions. Impeller or Air Type.